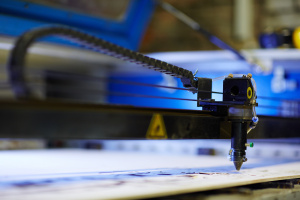

In today’s manufacturing world, CNC routers have revolutionized product design and manufacturing. These advanced machines are known for their ability to carve intricate patterns and make precise cuts. As a result, CNC routers have become indispensable across various industries, from woodworking to aerospace engineering.

But what makes CNC routers truly exceptional among the many options available? This article explores what distinguishes them: their unparalleled precision and accuracy.

As manufacturers and users seek ways to boost efficiency and minimize waste, understanding these machines’ capabilities becomes essential.

Whether you are an experienced manufacturer or new to the industry, discovering how CNC routers can transform your production process is vital.

Fundamentals of CNC Router Technology

Essential Components and Their Functions

The CNC router is a complex machine where every part plays a crucial role in achieving top performance, especially in precision and accuracy. Let’s look at three main parts: the spindle, frame, and software, and how they affect the machine’s abilities.

Spindle

The spindle is at the core of a CNC router. It does the actual cutting and carving of materials. The quality of the spindle affects cutting precision and its ability to stay consistent under different loads. High-quality spindles offer better speed and power control, which is crucial for achieving fine details and smooth finishes on projects.

Frame

The frame acts as the machine’s backbone, providing stability and support. A strong frame, usually made of welded steel, keeps the machine steady and free from vibrations during use.

This stability is vital for maintaining accuracy over time, as even small movements can disrupt cutting and cause errors. American-made CNC routers are known for their sturdy construction and durability.

Software

Software is the machine’s brain, translating digital designs into cutting instructions. Advanced software in CNC router systems allows for intricate pattern creation and precise control over cutting paths. This improves cutting precision and reduces the chance of errors, ensuring each piece is made exactly as planned.

Each part, from the spindle to the software, works together to achieve the precision and accuracy expected from high-quality CNC routers. Understanding how these parts contribute is crucial for users aiming to get the most out of their CNC router. Whether in a small woodworking shop or a large industrial setting, these parts’ synergy defines production efficiency and quality.

Types of CNC Routers and Their Specializations

CNC routers come in different types, each suited to specific needs and materials.

Desktop CNC Routers

These routers are ideal for hobbyists or small businesses, mainly for low-production work. They are perfect for detailed designs where precision matters, though they are on a smaller scale.

Industrial CNC Routers

These CNC routers are made for heavy-duty tasks, handling higher production output and tougher materials like non-ferrous metals and dense woods. These CNC router models are for large-scale production, where precision and maintaining accuracy at high speeds are crucial.

Choosing between them depends on the user’s specific precision and material needs. This ensures that every CNC router machine fits its intended purpose perfectly.

Measuring Precision in CNC Routers

What Does Precision Mean in CNC Routing?

In the context of CNC routing, precision refers to how accurately a machine can reproduce a design according to specified dimensions and tolerances. It measures how closely a CNC router can match the intended measurements and final design during the cutting process. Precision is not just about hitting the exact mark once but doing so consistently across multiple operations.

Repeatability is vital for precision. It is about the machine’s ability to consistently produce the same results without deviation during repeated operations. High repeatability means that each part or product is nearly identical.

This is crucial in industries needing uniformity, such as automotive or aerospace manufacturing. Achieving high repeatability reduces waste and boosts efficiency, as there is minimal need for adjustments between runs.

Key Factors That Affect Precision

Several factors impact a CNC router’s precision:

- Machine Calibration: Regular calibration ensures the CNC router aligns precisely with the design file’s coordinates, preventing dimension errors in finished products.

- Maintenance: Regular upkeep of mechanical and electronic parts like spindles and bearings maintains optimal function, preserving precision. Dust accumulation can interfere with mechanical movements and sensor accuracy.

- Setup: Proper material fixture and tool installation are crucial. Incorrect setup can cause material shifts during cutting, leading to inaccuracies.

- Environmental Factors: Changes in temperature and humidity can affect material properties. An example is MDF which swells with an increase in humidity.

- Operator Expertise: Skilled operators can enhance machine performance through precise adjustments and efficient problem-solving during routing.

These elements are crucial for ensuring that a CNC router performs at its best, consistently delivering products with exceptional precision and accuracy.

Achieving Accuracy with CNC Routers

Understanding Accuracy in Machining

Accuracy in CNC routing is about making sure the final product closely matches the intended design. It is different from precision, which is about consistency. Accuracy means the actual cut is very close to the target measurements.

For example, if a CNC router is supposed to cut a 10-inch circle, high accuracy means the cut circle is almost exactly 10 inches across.

Repeatability, on the other hand, is about consistency. Even if a CNC router does not cut exactly 10 inches every time, it can still be precise if it consistently cuts the same size circle.

Both accuracy and repeatability are important in machining to ensure designs meet exact specifications and are consistent in quality.

Strategies for Enhancing Accuracy

Improving the accuracy of a CNC router involves using better technology and having skilled operators. Here are some key strategies:

- High-Quality Cutting Tools: Using sharp, durable cutting tools reduces mistakes and improves the quality of cuts.

- Advanced Software Algorithms: Sophisticated design software algorithms give precise control over tool paths. These ensure that the router follows the intended pattern with few mistakes. Automated calibration features can also fix machine drift.

- Operator Skill: Skilled operators can adjust CNC routers for the best performance. This includes setting up materials properly, choosing the right tool speeds, and making small changes during cutting.

- Software Settings: Setting the right tool parameters and managing speed and feed rates are crucial for accurate cuts. Different materials need different settings to reduce mistakes.

- Regular Calibration and Maintenance: Keeping the CNC router calibrated and maintained ensures all parts work well, reducing mistakes from wear and tear.

Using these strategies, both manufacturers and hobbyists can make sure their CNC router consistently makes products with high accuracy, meeting the tough standards of modern manufacturing.

Expectations from Top-tier CNC Routers

Advanced Features That Define Top-tier Models

When it comes to CNC routers, the best CNC routers stand out because they have advanced features that make them more effective and accurate. Here are some of those features:

- Advanced Machine Controller: Acts as the brain of the CNC router, allowing precise control over cutting and making complex designs easier.

- High-Performance Servo Drive Systems: These systems respond quickly and accurately, ensuring cuts are smooth and precise.

- Auto Tool Changers: These let you switch between tools without stopping, keeping work moving smoothly.

- Advanced Material Hold Down Systems: These systems keep materials secure during cutting, preventing mistakes caused by shifting.

- Auto Lubrication Systems: These systems automatically oil moving parts, reducing wear and tear and keeping the machine accurate over time.

- Highly Configurable: Can be adjusted to work with different materials and designs, so you can set it up how you need it.

- Superior Dust Collection Mechanisms: Keep the workspace clean and clear so you can see what you are doing and avoid mistakes caused by debris.

These features make a CNC router faster, more efficient, and more reliable, ensuring precise and accurate results every time.

Software and Automation in Top-tier CNC Routers

Advanced software and automation are key to getting the most out of high-quality CNC routers. One important part of this is adaptive feedback systems. These systems keep an eye on the cutting process and adjust settings automatically as needed. This keeps accuracy high and reduces waste, making the router work better overall.

Another big feature is the Internet of Things (IoT) capabilities. These let CNC routers connect to a network so they can be monitored and operated remotely. This connection is important for fixing problems quickly and making adjustments, which makes the router more productive and efficient.

Predictive maintenance is another key aspect. It uses data analysis to predict when the router might have problems before they happen. This proactive approach stops downtime and keeps the router working well for longer.

All these software and automation features make sure that quality CNC routers meet the highest standards of precision and accuracy.

Conclusion

CNC routers play a big role in how well things are made in manufacturing. They are known for their advanced features like adaptive feedback systems, high-performance drives, and smart software. These routers ensure that things are not just precise but consistently accurate, meeting the exact needs of different industries.

As CNC technology improves, we can expect even more precise and accurate machines. Most of these American-made CNC routers will likely have more automation, better ways of handling materials, and easier-to-use software, pushing the limits of what CNC can do.

Want to improve the precision and accuracy of your manufacturing? Consider getting a USA-made CNC router! Contact CAMaster to learn more.

1-866-405-7688

1-866-405-7688