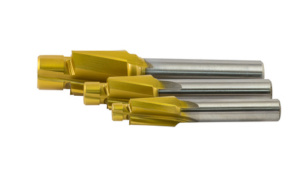

If you’re preparing to use your CNC machine for some milling projects, the first thing you need to do is buy some good cutting tools. To start out with, you will need a set of reliable cutters for a reasonable price. If you are a newcomer to milling, it’s best to start out with end mills made from high speed steel (HSS) to begin with, as they are less costly and more ... Read More

1-866-405-7688

1-866-405-7688