Foam Cutting

Foam Cutting with a CAMaster CNC Router

Our CNC routers can handle any sort of design or application requiring accurate and precise foam cutting

Reliable and Accurate Foam Cutting Solutions

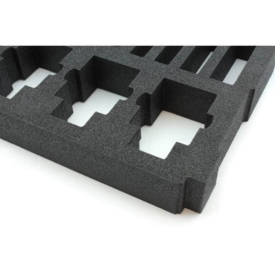

From routing protective foams to producing ETS molds, CAMaster has a CNC platform that can help increase productivity using an automated manufacturing solution. For any kind of production requirement or foam cutting application, our CNC routers come with expert technical support and a variety of efficient extras.

CNC Routers for Every Foam Cutting Application

Cutting foam on a CNC router can be challenging. Depending on how porous the material is, you’ll want a solution that keeps the foam securely in place and provides consistent results every time. Vacuum tables and deck arrangements can ensure the foam remains stable throughout the entire machining process.

Depending on the quantities required or type of materials used, choose from any of our CNC router platforms to find the ideal solution.

Our CNC routers help companies to:

- Manufacture packaging foams for tools, instruments, and electronic products

- Machine ETS molds for new product development

- Quickly change cutters and routers for increased efficiency

Expert Technical Support with Every CNC Router

We build our CNC routers to be robust, reliable, and vibration-free. CAMaster will work with your team to find an ideal solution that can boost your productivity without compromising your product quality.

Our dedicated technical support staff will:

- Ensure you find the ideal solution that supports your entire manufacturing process

- Support your organization and resolve technical issues quickly

- Recommend additional options to maximize your company’s output

Designing the Best Solution for Your Business

Along with our wide array of platforms, we provide additional options to ensure you can configure the best CNC router for your specific foam cutting application.

Additional options include:

- Laser crosshairs to help you quickly set the X-Y axis starting position

- Z-A counterbalance to keep all forces equalized during operation

- Phenolic tabletop options to prevent bleeding air from your vacuum table

- A variety of vacuum pumps, pod systems, and tables to choose from

We also have mister systems, popup locating pins, automatic lubricating systems, and aggregate tools for horizontal or angle cutting. With more than 50 years of experience with CNC routing machines and setups, CAMaster can support any unique machining requirement you may have.

Suitable for All Types of Foam Cutting and Processing

Choosing the right CNC router for your business depends on your exact requirements. CAMaster will assist with the CNC router selection, advising on additional options for the specific application, and guide your team during every step of the process.

Some of the benefits of using a CNC router for foam processing are:

- Adaptable platforms that work equally well with different materials, including hard-density foams or light, cushy polyethylene

- Ensures clean edges and cuts into any type of foam material

- Different spindle configurations and automation options to keep your team running smoothly

CAMaster Will Solve Your Foam Cutting CNC Routing Issues

With the challenges of cutting foam with a CNC router, CAMaster has the experience and technical expertise to help you overcome any issue. Our machines provide you with maximum flexibility while support staff are ready to assist with any question or request you may have. With decades of experience and a complete suite of customizations available, our team can be your dedicated CNC router supplier for any project.

To discuss your CNC routing needs or get advice on what platform will support all your foam cutting needs, speak to one of CAMaster’s experts today.

1-866-405-7688

1-866-405-7688